Alloy & Tool Steel

Alloy & Tool Steel refers to steel that contains a significant amount of alloying elements (such as chromium, nickel, molybdenum, vanadium, titanium, etc.) to improve its properties, giving it special characteristics such as high strength, corrosion resistance, wear resistance, and more. The addition of alloying elements allows alloy steel to be tailored for various industrial applications, including manufacturing, automotive, aerospace, and construction.

1. Properties of Alloy & Tool Steel

The properties of alloy steel are largely determined by its alloy composition and manufacturing process. Common properties include:

High Strength and Hardness: Alloy steel often has superior strength and hardness compared to carbon steel, making it suitable for applications that require resistance to high mechanical loads.

Corrosion Resistance: Certain alloy elements (such as chromium and nickel) enhance the corrosion resistance of the steel, making it suitable for use in harsh environments, including high-temperature, oxidative, or chemically corrosive conditions.

Wear Resistance: Alloy steels exhibit excellent wear resistance, particularly those with elements like molybdenum and vanadium, making them suitable for manufacturing high-wear tools and equipment.

Thermal Stability: Alloy steels maintain good strength and hardness at high temperatures, making them ideal for components operating under high-temperature conditions.

Toughness: Some alloy steels are designed to improve toughness, allowing them to withstand impact and vibrations without cracking or breaking.

2. Types of Alloy & Tool Steel

Alloy steel can be classified based on the type and content of alloying elements, typically into the following categories:

a. Low-Alloy Steel

Low-alloy steels contain up to 5% of alloying elements. These steels mainly improve general properties like strength, toughness, and wear resistance, while maintaining a lower cost. Examples include:

Q235 Steel: Widely used in construction and bridge structures.

16Mn Steel: Often used for manufacturing mechanical parts under medium to high loads.

b. Medium-Alloy Steel

Medium-alloy steels contain between 5% and 10% of alloying elements. They offer higher strength, hardness, and corrosion resistance, making them suitable for mechanical manufacturing and automotive applications. Examples include:

20Cr Steel: Commonly used for gears, shafts, and other mechanical parts.

40Cr Steel: Used in high-strength mechanical components, such as drive shafts and engine parts.

c. High-Alloy Steel

High-alloy steels contain more than 10% of alloying elements, providing significant improvements in specific properties like corrosion resistance, high-temperature performance, and wear resistance. Examples include:

Stainless Steel: Primarily alloyed with chromium, known for its excellent corrosion resistance. It is widely used in chemical processing equipment, food processing, and medical devices.

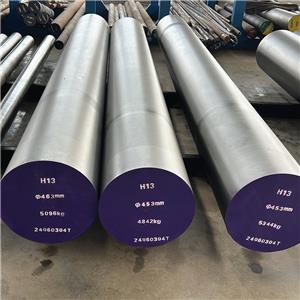

Tool Steel: Contains higher amounts of tungsten, molybdenum, chromium, and vanadium to provide high hardness and wear resistance, ideal for manufacturing cutting tools and molds.

3. Applications of Alloy & Tool Steel

Due to its superior mechanical properties and special characteristics, alloy steel is used in various industries, with common applications including:

Mechanical Manufacturing: Alloy steels are used to manufacture automotive parts, engine components, drive shafts, gears, and bearings. High-strength alloy steels can withstand significant mechanical loads while maintaining good wear resistance.

Construction and Infrastructure: Low-alloy steels are commonly used in the construction of buildings, bridges, and other structural elements. Their good workability and weldability make them ideal for load-bearing structures.

Aerospace: Alloy steels are used in aerospace components such as aircraft wings, engine parts, and missiles. High-alloy and heat-resistant steels are particularly effective at high temperatures.

Petrochemical Industry: Alloy steels are used in petroleum extraction and chemical processing equipment due to their high corrosion resistance, high-temperature strength, and resistance to harsh chemicals.

Energy Sector: Alloy steels are used in nuclear power, thermal power, and other energy sectors for manufacturing boilers, pressure vessels, and pipelines. High-temperature alloys are particularly suitable for extreme working conditions.

Tools and Molds: Alloy steels are widely used in the production of cutting tools, molds, and gauges. Tool steels and mold steels contain higher levels of tungsten, molybdenum, chromium, and vanadium to ensure exceptional wear resistance, impact resistance, and high-temperature stability.

4. Common Alloy & Tool Steel Materials

Cr-Mo Steel (Chromium-Molybdenum Steel): Known for its excellent wear resistance, strength, and toughness, often used for manufacturing high-load mechanical components.

Ni-Cr Steel (Nickel-Chromium Steel): Offers higher strength, toughness, and corrosion resistance, widely used in automotive engine components, drive shafts, etc.

AISI 4140 Steel: A commonly used alloy steel with good overall performance, including high strength and toughness, often used for mechanical parts and tools.

AISI 4340 Steel: A high-strength alloy steel used for aircraft and automotive structural components such as engine parts and flight vehicle components.

Stainless Steel (e.g., 304, 316): Offers excellent corrosion resistance and is widely used in chemical processing, food handling, and medical equipment industries.

5. Selecting Alloy & Tool Steel

When choosing alloy steel, several factors should be considered:

Mechanical Performance Requirements: Such as strength, hardness, wear resistance, etc.

Working Environment: Whether the steel needs to resist corrosion, high temperatures, or low temperatures.

Manufacturing Process: Considerations regarding the weldability, machinability, and formability of the alloy steel.

Cost Effectiveness: Balancing the cost of the alloy steel with its required performance characteristics.

Summary

Alloy steel, with its combination of alloying elements, significantly enhances the strength, corrosion resistance, wear resistance, and other special properties of steel. It is widely used in various industrial fields, including mechanical manufacturing, construction, aerospace, petrochemical, energy, and tools and molds. Based on alloy composition and intended use, alloy steel can be classified into low-alloy, medium-alloy, and high-alloy steels, each serving specific application needs.