SKD5 (a high-alloy hot-work tool steel) Applied In Precision Forging Molds

SKD5, as a high-alloy hot-work tool steel, holds a significant position in the industrial manufacturing field due to its exceptional performance.

1. Basic Information

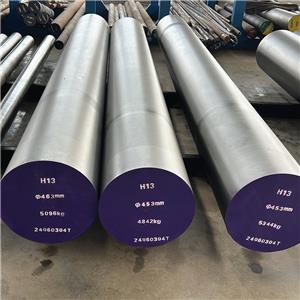

Grade: SKD5

Standard: JIS G4404

Equivalent Grades:

China GB: 3Cr2W8V

U.S. ASTM: H21

Germany DIN: 1.2581

2. Chemical Composition

The chemical composition of SKD5 is as follows:

Carbon (C): 0.30~0.40%

Silicon (Si): ≤0.40%

Manganese (Mn): ≤0.40%

Phosphorus (P): ≤0.030%

Sulfur (S): ≤0.030%

Chromium (Cr): 2.20~2.70%

Tungsten (W): 7.50~9.00%

Vanadium (V): 0.20~0.50%

These components work together to provide SKD5 with high hardness, excellent heat resistance, superior wear resistance, and high impact toughness.

3. Mechanical Properties

The mechanical properties of SKD5 are as follows:

Yield Strength (Rp0.2): ≥333 MPa

Tensile Strength (Rm): ≥355 MPa

Impact Energy: 14 J

Elongation: 32%

Reduction of Area: 24%

Heat Treatment State: Solution and aging, annealing, Ausaging, Q+T, etc.

Brinell Hardness (HBW): 121

4. Physical Properties

The physical properties of SKD5 include:

Elastic Modulus: Approximately 211 GPa at room temperature

Thermal Conductivity: Approximately 41.3 W/m·K at room temperature

Specific Heat Capacity: Approximately 421 J/kg·K

Electrical Resistivity: 0.33 µΩ·m

Density: Approximately 7.85 g/cm³

These physical properties enable SKD5 to maintain excellent performance under high-temperature and high-pressure conditions.

5. Heat Treatment

The heat treatment of SKD5 typically includes:

Quenching: 1075~1125°C, oil cooling

Tempering: The tempering temperature and duration vary depending on specific application requirements.

Proper heat treatment can significantly enhance the hardness and wear resistance of SKD5.

6. Applications

SKD5 is widely used in:

Die-casting Molds: Especially for aluminum and magnesium alloy die-casting molds.

Hot Extrusion Molds: Suitable for extrusion molds operating under high-temperature and high-stress conditions.

Precision Forging Molds: Used for non-ferrous metal forming molds, etc.

Cutting Tools: Used in the manufacturing of various cutting tools, such as drill bits, milling cutters, and turning tools.

7. Surface Treatment

SKD5 can undergo surface treatments as needed, such as:

Grinding: Improves surface finish.

Polishing: Further enhances surface smoothness and aesthetics.

Nitriding: Increases surface hardness and wear resistance.